Do you have to install porcelain stoneware for several square meters and you don’t know which type of machine is better for your use?

We can find on the market many different cutters in shape, size, or with/without an electric motor. Each of them has specific features and choosing the right model, suitable for your needs, can be complicated.

In particular, the three fundamental characteristics that must be taken into consideration are:

- use with electric motor or manual use,

- tile shape to be cut,

- budget

Sometimes a simple cutter can be useful, but in other cases you need to focus on more powerful models.

If we make a successful purchase, the tile cutter allows a significant saving on labor costs and an advantage in terms of reduction of tile waste, as well as speed of execution. Last but not least, versatility in terms of weight and ease of transport.

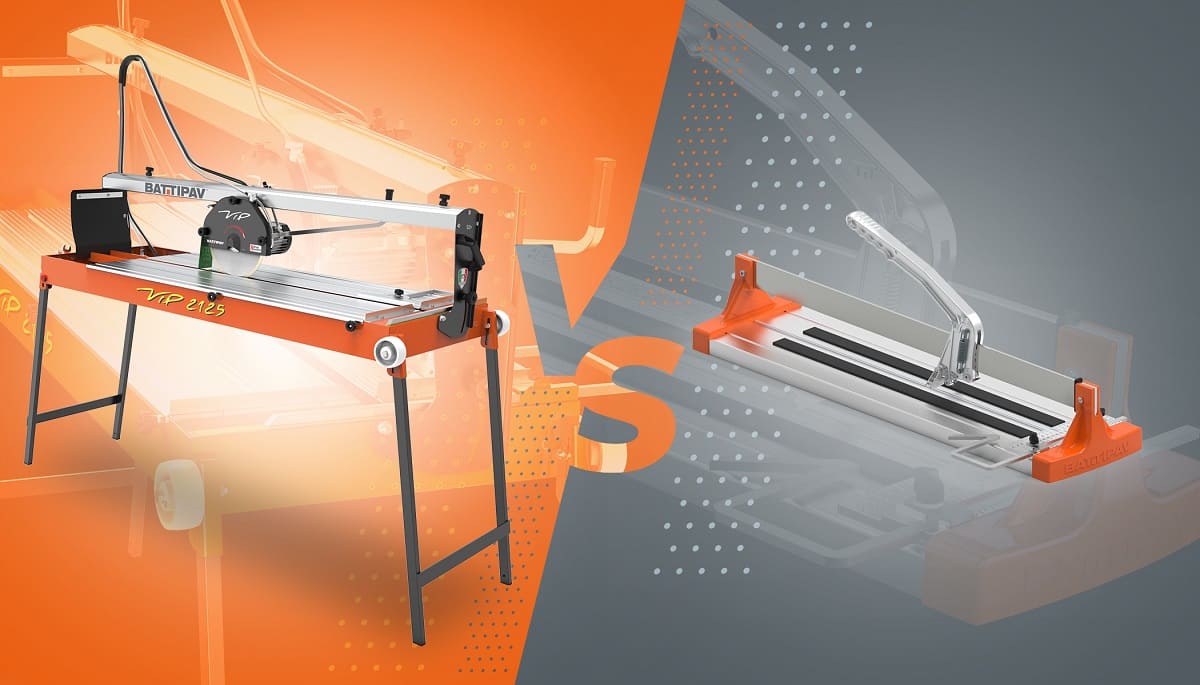

Electric tile cutter: pros and cons

Electric tile cutters are chosen for many reasons, the main ones are:

- speed in the execution of the cut,

- extreme precision.

On the other hand, a problem to be carefully evaluated is the need for electricity to activate them. In fact, their motor absorbs up to 1.4 kw making it more complex to use on small construction sites. Also, by functioning with cooling water, you have to do a lot of cleaning while using it and maintenance every time you finish working.

Which electric tile cutter to choose

Here at Battipav we have developed many models of electric tile cutters for all types of construction sites.

You can start from an Entry Level with a steel frame but with a professional engine always made internally: all qualities present in the VIP range, with a ø 200mm disc, precise and super easy to use. Perfect for straight and 45° cuts and for inserts that can also be made in the center of the tile thanks to the tilting movement of the motor head.

The new VIP 2125 was created instead for slabs up to 125 cm in length. Made with an even more powerful motor, It also has an aluminum worktop to ensure quick cleaning of the tank in a single move.

Just remove it by simply unlocking it from the tank and that’s it. The specific professional disc for marble cutting is already included in the price! See all the features here

If you are looking for an electric tile cutter completely in aluminum, we recommend the CLASS range: always with a 200 mm diameter disc included, it is a machine with an attractive design and with the possibility of having it also with the convenient laser kit and transport wheels (“S” version of the range). In this way it will be easy to move it without the help of a second operator.

CLASS is the perfect fit between the VIP and the even more professional CLASS PLUS: with a really powerful motor to give strength to a 250 mm diameter disc, this machine might be able to cut the first marble slabs! Another plus of having the aluminum structure makes the problem of rust a far memory. Matter that is important to those who work in maritime or very rainy areas.

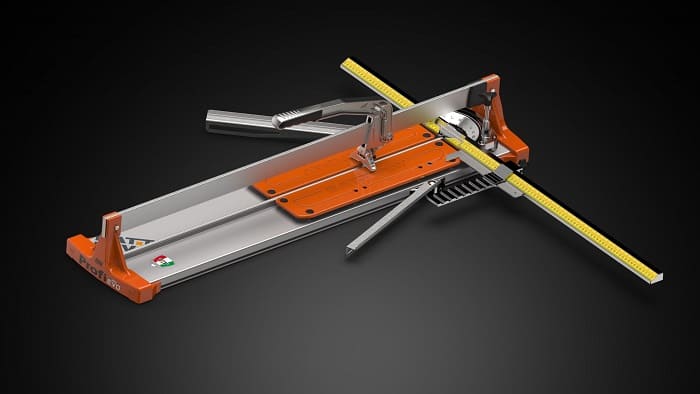

Manual tile cutter: pros and cons

The manual ones are very practical and easy to use, as you only need to place the tile on the support base, and then make a clear incision with the cutting wheel and separating the two parts with a simple pressure of the breaking foot.

They are not used with water and can be carried easily by simply lifting them off the ground by the slide bar. We can also provide a practical bag to store your favorite machine in!

They are ideal for small construction sites and for making cuts on tiles that are not particularly thick and hard. On the other hand, it must be considered that intensive and prolonged use can be tiring, since cutting requires the use of physical strength.

Which manual cutter to choose

As Entry level in this case we offer the LEGGERA range, ideal for small jobs and limited budgets. With an essential, simple and comfortable design, it is perfect for cutting narrow and long tiles up to 137 cm. Furthermore, being made entirely of aluminum, the creation of rust is avoided in the long period of use even outdoors!

The SUPER PRO EVO, on the other hand, becomes interesting for professionals who require an excellent dose of precision and speed of use. The body of the machine remains essential, always with the base in extruded aluminum, while the carriage contains 9 ball-bearings for a unique stability and smoothness of cutting.

Finally, the PROFI EVO is considered the top of the range. Loved all over the world, it is depopulating in terms of design, professionalism and technical characteristics starting from the very comfortable handle, up to the aluminum breaking foot including the magnet, useful in the cutting phase, and the solid side supports that support tiles up to 1,2 meters wide and 1.6 meters long.

Two further strengths are the weight and the price: much lighter than the competition and therefore even easier to transport, we offer it at a really advantageous market price.

If you want to request a personalized and even more in-depth consultation, contact us!

Error: Contact form not found.