| Max cutting lenght | 800 mm |

|---|---|

| Pallet ref. | |

| Max cutting thickness | 110 mm |

| Max cutting depth for 45° (jolly) cut | 80 mm |

| Diamond blade diameter | Ø350 mm |

| Tool hole | Ø25,4 mm |

| Power engine | 3Hp/2,2Kw, 9A |

| Machine's dimension in stock | 71x118x81 cm |

| Engine type | SINGLE-PHASE 230V~50Hz |

| Laser instrument | Standard |

| Machine's dimension | 1240x900xH1300mm |

| Max cutting depth with 2 RUNS | 130 mm |

| Weight | 68 Kg |

| Packaging | 1 pz |

| Packaging dimension | 80x120x97 cm |

| Pallet dimension | 80x120x226 cm |

| Pieces for pallet | 3 pz |

| Pallet gross weight | 224 Kg |

| Size tile for diagonal cutting | 435×435 mm (H. max 40 mm) (H. 130=400×400 mm) |

| Amperometric protection | 13 A |

| Rotation speed | 2800rpm |

| Side bench dimesion | 442x520mm |

| Thermic protection | 160°c |

| Water pump | S2 |

| Water tank capacity | Min. 19 / Max. 25 liters |

| Wheels | Optional |

| Fence | Standard |

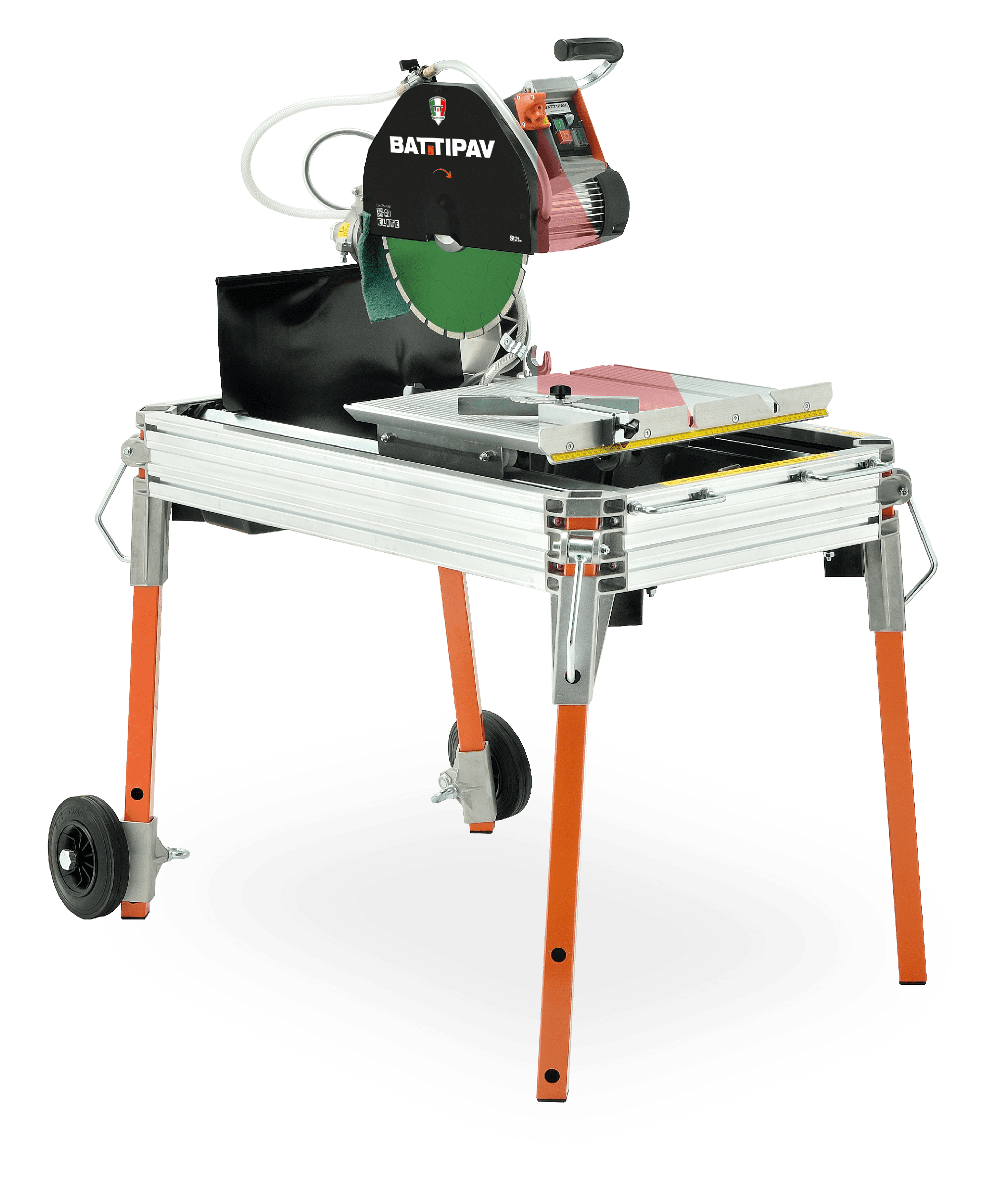

ELITE 80 is a masonry saw ideal for the building sector. Ergonomic design with van technical innovations, compact and strong, it’s suitable for cutting bricks, stones, concrete-blocks, granite, marble and natural stones. It makes cuts pushing the sliding working table or tilting the cutting head. It’s planned to work with disks Ø 350 mm. and, according to the version, laser instrument and kit wheels are supplied standard or as optionals.

Equipped with:

– Single phase engine 230V 50Hz 3Hp/2,2 Kw with thermal and amperometrical protection

– Switch with release coil.

– Overheat protection with manual reset

– Sliding working table and tilting cutting head.

– Laser instrument

– Kit wheels

– Adjustable legs

– Adjustable goniometer fence

– Water recycling pump type S2

Water cooled

Disk Ø 350 mm not included

Three phase engine available upon request