Mission

Promotion of the brand, production and supply of tiling tools and equipment of highest quality, as the best expression of “made in Italy”, compose the main mission of the Battipav company.

Vision

Continuous innovation, evolution and development are the main traits of the vision of Battipav, which wants to be the best Partner of every professional in the building field, able to offer the best quality technical solutions 100% made in Italy with the unsurpassed value for money ratio and high attention to safety and comfort.

Sales Director

Area Manager

Customer care

Il Team Battipav

The history of a company usually traces the life of a few men; the success of a company describes its capabilities.

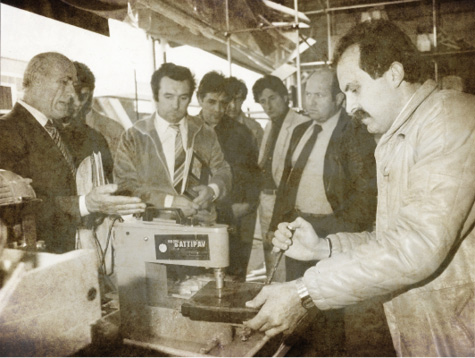

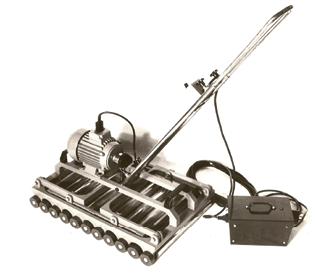

Battipav was founded in the 1970s as a manufacturer of roller tile beaters for levelling ceramic tiles on floors.

In 1980 the company’s headquarters moved to Cotignola in a small structure used as a warehouse, hence the change of the brand name to “Nuova Battipav”.

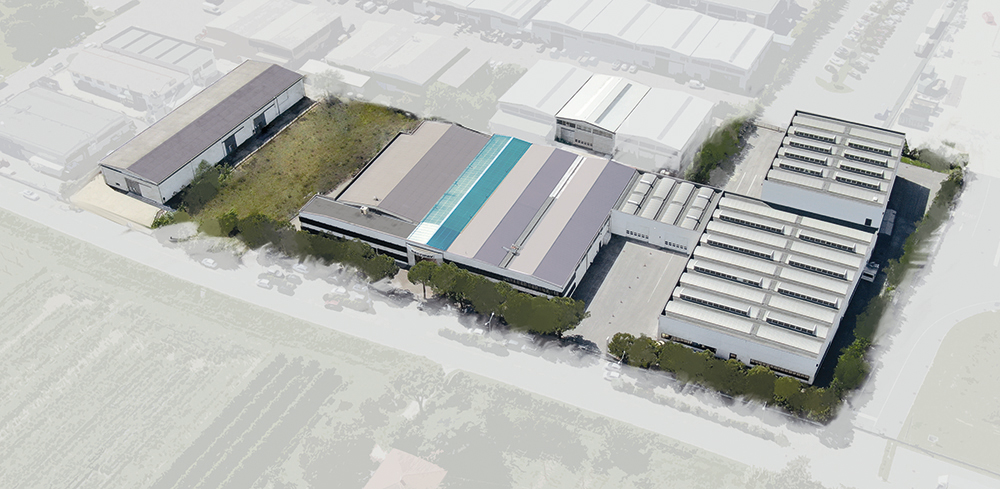

From this moment on, Mr. Tondini decided to completely take over the company and move it to its current location, initiating a series of structural expansions.

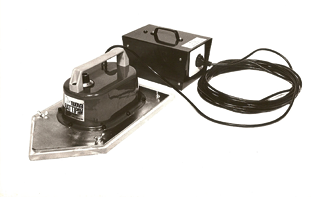

With the addition of cutting machines to the range, a new challenge arose: the creation of submerged pumps, essential for lubricating the discs of electric cutters.

After about twenty years, Battipav is a leader in the submersible pump sector.

At the end of the 1990s, the company’s core business shifted, concentrating most of its energies on research, development and production of machines for cutting blocks, marble and bricks.

MADE IN ITALY

All Battipav products are studied, designed and manufactured in made in ITALY. An element of great pride for a company that intends to make as its workhorse, its production strictly MADE in ITALY.

Today, after more than 30 years, the company covers an area of about 14000 square metres, of which more than 9000 are covered, and distributes its products in more than 90 countries.

QUALITY, RELIABILITY, INNOVATION

The philosophy of construction and design for Battipav is something very solid and important.

A series of strict quality controls, throughout the production process, allows us to have zero defects, for TOTAL RELIABILITY.

Each of our machines is therefore covered by a 24-month WARRANTY.

2018

The new tricolor shield embodies Battipav’s corporate mission, based on providing high quality Made in Italy products.

2010

After a long research with professionals of the sector, after 12 years, the company brand is revised in a more modern and professional key, giving life also to an integrated logotype on which the company will invest resources and energies to further distinguish itself on the world scene.

1990

Since the end of the ’90s the brand has acquired linearity and regularity, a mandatory change to keep up with the times.

1980

At the end of the 80’s this logo was accompanied by the design of the installer who is satisfied with his work thanks to the use of our machines.

1970

The resourcefulness of a company can also be seen through the evolution of its brand. The first Battipav logo, dating back to its foundation, represented a little elephant on the world; the quivering footsteps of the pachyderm recalling the vibrations of the JUMBO VARIOMATIC roller tile beater, an innovative product at the time for traditional laying on cement screed.

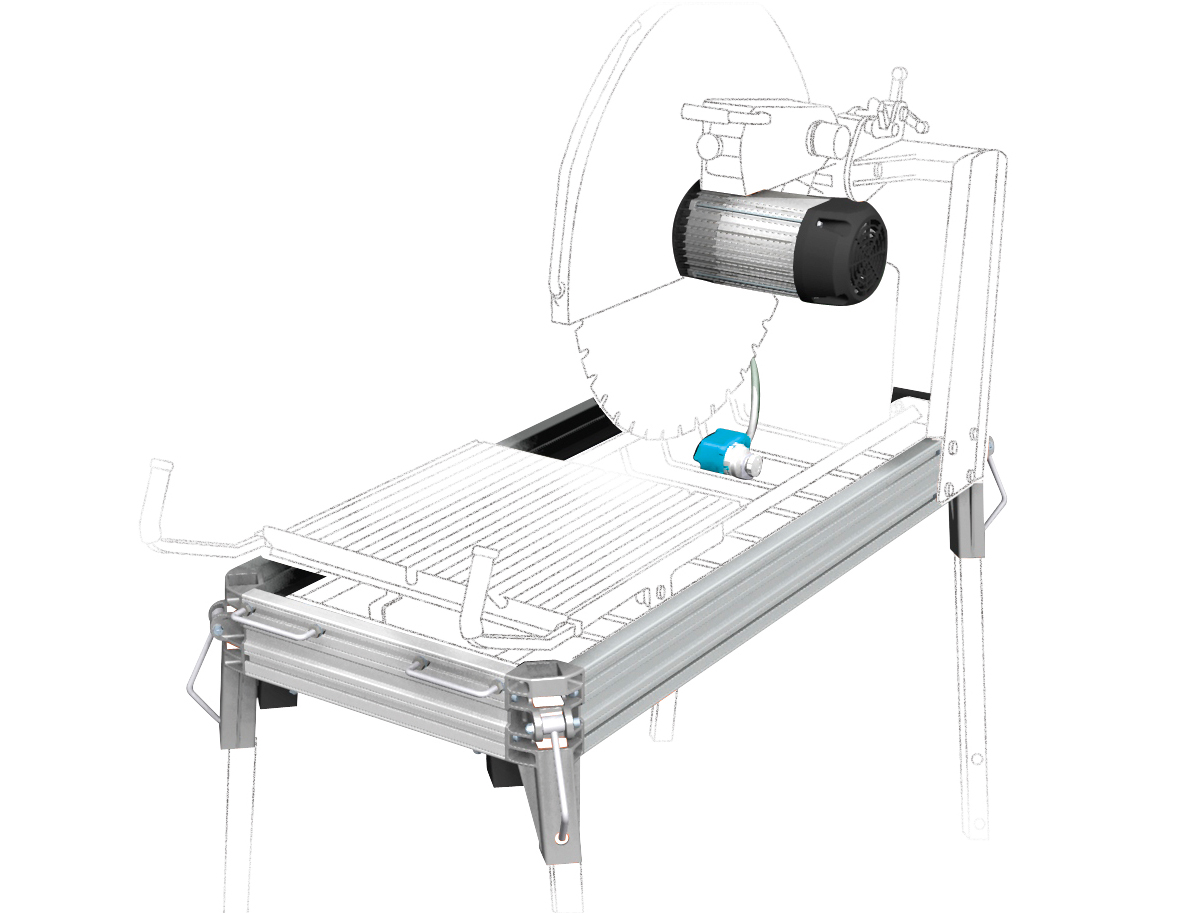

FAST LEG

The system which makes the storage of the machine much easier. This system ensures more rigidity and steadiness when operating, and allows to stack up to three machines on one pallet. This reduces the encumbrance of the machine by eliminating the packaging.

SPRAY SYSTEM

Diamond blade cooling system. It works on the three vital points of the diamond tool: on the front and on both sides of the rim. It has great efficiency also in the mitre (45°) cuts. It prevents cutting dust and improves the life of the diamond tool, by creating a flow of misty water inside the blade guard.

W-DEC

Water-decanting system:

The original shape of the water tray prevents the grout to accumulate in the pump area, so allowing the pump to use always clean water.

AxT

(Water for Cutting): this trademark represents the winning association between submersible pump and masonry saw. The trademark symbolizes originality and high quality.

ELECTRIC MOTOR

BATTIPAV is the only company on the market to fully manufacture its own electric motors.

Designed and developed specifi cally for the service they are providing, with HIGH PERFORMANCE at the RIGHT ABSORPTION and with a shape and size capable to be 100% INTEGRATED in our frames.

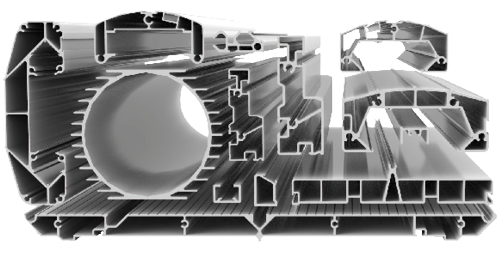

ALUMINIUM

Lower weight: handling and stability maintaining the required structural strength.

Patented profile that permits an easy mounting with no welds

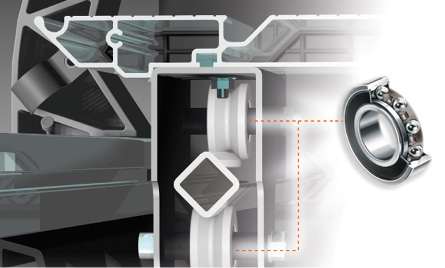

TECHNOLOGY AIMING TO PRECISION

All our machines are extremely precise: all the carriages, from manual tile cutters to sliding tables (on masonry saws) and motor supports (on bridge saws) are equipped with steel ball bearings in order to guarantee the highest precision, the smoothest movement and a long life.

DESIGN PHILOSOPHY

Battipav is proud to design, develop and manufacture the most important components of any electric saw and manual tile cutter, inside their factory.

ELECTRIC SAW

Electric motor: designed inside our Research & Development Dept., according to the specific requirements of our machines.

Electric motor: designed inside our Research & Development Dept., according to the specific requirements of our machines.

Every part is assembled and tested by our technical staff.- Frame: patented, made of innovative extruded aluminium, according to the requirements of

very solid and rigid.

very solid and rigid. - Pump:

professional pump for diamond blade cooling. It is fully manufactured inside our factory.

professional pump for diamond blade cooling. It is fully manufactured inside our factory.

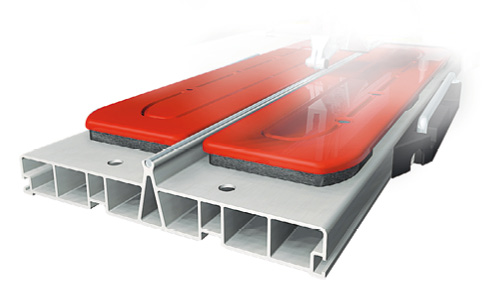

MANUAL TILE CUTTER

- Strong body: made in aluminium draw-plate to get the maximun of rigidity and lightness at the same time.

- Interchangeable stainless steel cutting line